Submit

Submit feedback

Aluminum Alloy Wheels: Understanding the Options

2025-01-10

China Sale Aluminum Alloy Wheels Factory Manufacturer

The automotive industry is a testament to human innovation, with constant advancements in technology and design. One of the noticeable aspects of a vehicle is its wheels, which not only serve a functional purpose but also contribute to the aesthetic appeal. Among the various materials used for wheels, aluminum alloy wheels factory have become increasingly popular due to their strength, lightness, and durability.

Types of Aluminum Alloy Wheels

Aluminum alloy wheels are classified based on several criteria, including their manufacturing process, design, and intended use. Here, we will explore the main categories of aluminum alloy wheels and their distinguishing features.

Cast Aluminum Alloy Wheels

Cast wheels are the common type of aluminum alloy wheels. They are produced by pouring molten aluminum alloy into a mold and allowing it to cool and solidify. This method is cost-effective and allows for a wide range of designs.

a. Low-Pressure Die Casting (LPDC) Wheels

- These wheels are made using a low-pressure die casting process, which ensures a more uniform distribution of material and fewer impurities. LPDC wheels are known for their strength and durability.

b. High-Pressure Die Casting (HPDC) Wheels

- HPDC wheels are produced under high pressure, which allows for faster production times. However, the high pressure can bring about a less dense structure, potentially affecting the wheel's strength.

Forged Aluminum Alloy Wheels

Forged wheels are made by heating a solid aluminum billet and then shaping it using a forging press. This process results in a denser and stronger wheel compared to cast wheels.

a. Fully Forged Wheels

- These wheels are entirely forged from a single piece of aluminum, offering exceptional strength and weight savings. They are often used in high-performance vehicles and racing applications.

b. Flow-Formed Wheels

- Flow-formed wheels start as a cast wheel, which is then spun at high speed and pressed against a rotating mandrel. This process creates a forged-like rim with a cast center, combining the benefits of both methods.

Multi-Piece Aluminum Alloy Wheels

Multi-piece wheels consist of two or more parts that are assembled together. They offer a high level of customization and can be lighter than one-piece wheels.

a. Bolt-Together Wheels

- These wheels are assembled by bolting together the barrel (rim) and the center disk. This design allows for a wide range of customization options.

b. Rivet-Together Wheels

- Similar to bolt-together wheels, rivet-together wheels are assembled using rivets. They offer a clean, seamless appearance with no visible fasteners.

Specialty Aluminum Alloy Wheels

Specialty wheels are designed for specific applications or to meet unique performance criteria.

a. Racing Wheels

- Racing wheels are lightweight and strong, often featuring a central locking system for quick tire changes.

b. Aerodynamic Wheels

- These wheels are designed to reduce air resistance, improving fuel efficiency and performance.

c. Winter/Snow Wheels

- Winter wheels are made to provide better traction and performance in cold, snowy conditions.

Benefits of Aluminum Alloy Wheels

Aluminum alloy wheels offer several advantages that make them a popular choice among consumers:

Lightness: Aluminum is lighter than steel, which can improve a vehicle's fuel efficiency and handling.

Durability: Aluminum wheels are resistant to rust and corrosion, ensuring a longer lifespan.

Heat Dissipation: Aluminum's thermal conductivity allows it to dissipate heat more effectively than steel, reducing the risk of brake fade.

Aesthetics: Aluminum wheels can be designed in various styles and finishes, enhancing the vehicle's appearance.

Recyclability: Aluminum is highly recyclable, contributing to environmental sustainability.

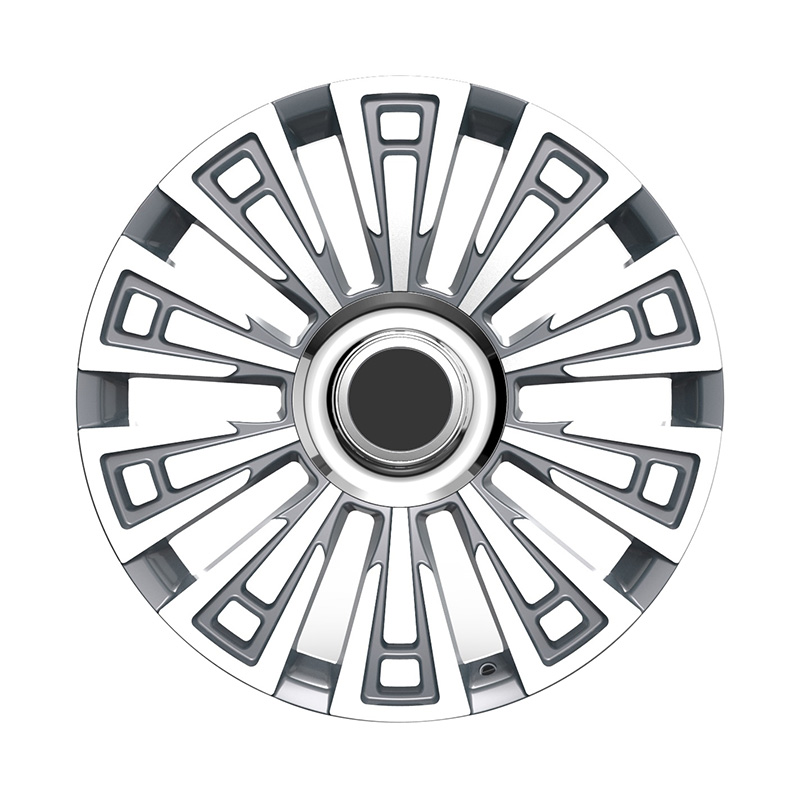

recommend products

-

Zhenlun Multi Spokes Split Monoblock Forged Wheels Bronze With Silver Lip Edge

-

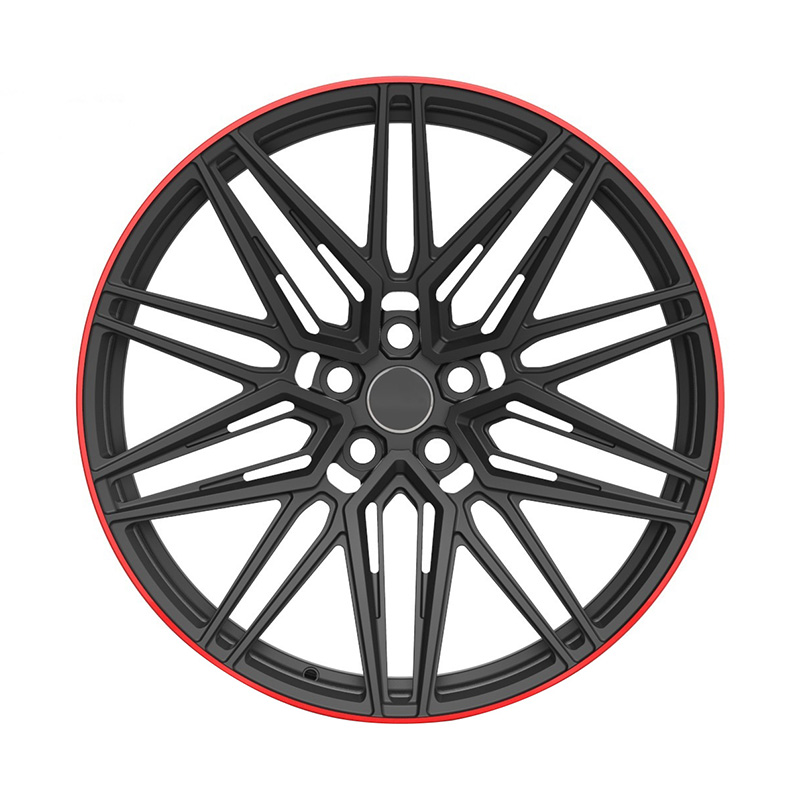

Zhenlun Matt Black With Red Lip Monoblock Forged Wheels

-

Zhenlun Gloss Black Monoblock Forged Wheels Gloss Black For Sports Car

-

Zhenlun Monoblock Forged Wheels Lightgrey With Machined Face

-

Zhenlun Monoblock Forged Wheels Gloss Black Dense Multi Spoke

0

0