Submit

Submit feedback

Aluminum Alloy Wheels: Performance, Aesthetics, and Innovation

2025-01-17

Wholesale Custom Aluminum Alloy Wheels Factory Supplier

Aluminum alloy wheels factory have become a staple in the automotive industry, offering a blend of performance, aesthetics, and durability that has made them a popular choice for both manufacturers and consumers alike. These wheels, constructed from a combination of aluminum and other metals, provide a lightweight alternative to traditional steel wheels, enhancing vehicle performance and fuel efficiency.

The Benefits of Aluminum Alloy Wheels

Lightweight Design

One of the significant advantages of aluminum alloy wheels is their lightweight nature. Compared to steel wheels, which are heavier, aluminum alloy wheels can reduce the overall weight of a vehicle. This reduction in weight bring about improved acceleration, better fuel economy, and enhanced braking performance. The lighter wheels also contribute to a decrease in the unsprung weight of the vehicle, which can bring about improved handling and ride comfort.

Heat Dissipation

Aluminum is an conductor of heat, which means that aluminum alloy wheels can dissipate heat more effectively than steel. This property is particularly beneficial for vehicles that are driven hard or for extended periods, as it helps to prevent overheating of the brakes and tires, thereby increasing safety and longevity.

Corrosion Resistance

Aluminum alloy wheels are more resistant to corrosion than steel wheels. The natural oxide layer that forms on aluminum when exposed to air acts as a protective barrier, preventing rust and other forms of corrosion. This resistance to corrosion not only maintains the aesthetic appeal of the wheels but also extends their service life.

Aesthetic Appeal

The sleek and modern look of aluminum alloy wheels is another reason for their popularity. They are available in a wide range of designs, finishes, and colors, allowing vehicle owners to customize the appearance of their cars to suit their personal tastes. The polished or painted surfaces of aluminum alloy wheels can give a vehicle a high-end, luxury look.

Applications of Aluminum Alloy Wheels

Passenger Vehicles

Aluminum alloy wheels are commonly used in passenger vehicles, from compact cars to luxury sedans. They are particularly popular in performance vehicles, where their lightweight design can provide a significant performance advantage.

Commercial Vehicles

In the commercial sector, aluminum alloy wheels are used in trucks and buses to reduce weight and improve fuel efficiency. The durability and strength of aluminum alloys make them suitable for the heavy loads and demanding conditions often faced by commercial vehicles.

Racing and Performance Vehicles

For racing and high-performance vehicles, aluminum alloy wheels are almost standard due to their lightweight and heat dissipation properties. They contribute to faster lap times and better handling, which are crucial in competitive racing.

Technological Advancements

Forged vs. Cast Aluminum Alloy Wheels

The manufacturing process of aluminum alloy wheels has seen significant advancements. Forged wheels, which are stronger and lighter than cast wheels, are now more commonly used in high-performance applications. The forging process involves shaping the aluminum under pressure and heat, resulting in a denser and stronger wheel.

Design Innovations

Advancements in design software and manufacturing techniques have allowed for more intricate and complex wheel designs. This has led to the creation of wheels with improved structural integrity and aesthetic appeal.

Surface Treatments

The surface treatments for aluminum alloy wheels have also evolved. Anodizing, painting, and powder coating are some of the methods used to protect the wheels and enhance their appearance. These treatments can also provide additional benefits such as resistance to UV rays and scratches.

recommend products

-

Zhenlun Multi Spokes Split Monoblock Forged Wheels Bronze With Silver Lip Edge

-

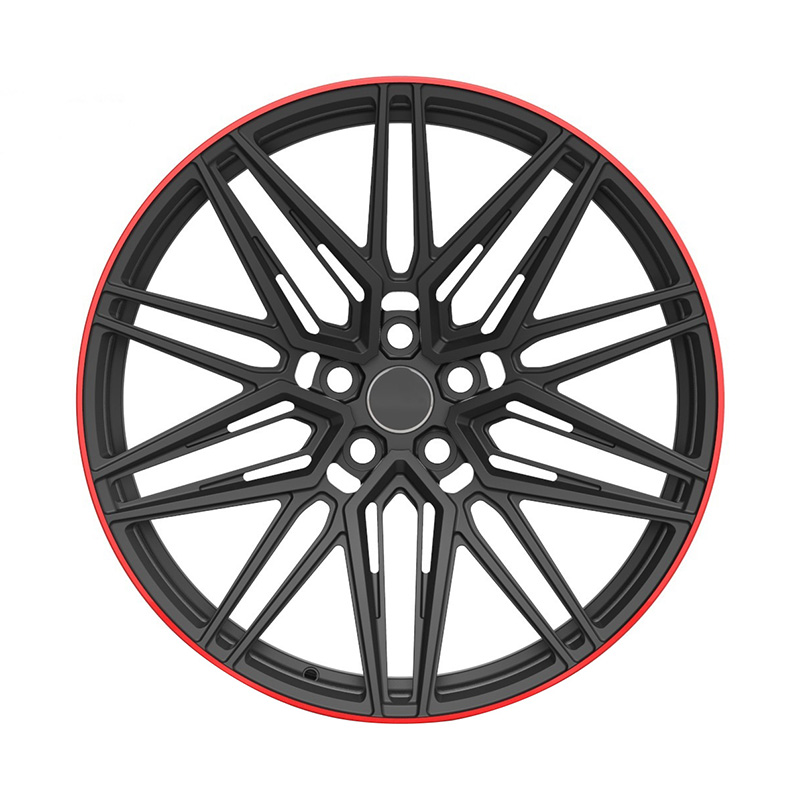

Zhenlun Matt Black With Red Lip Monoblock Forged Wheels

-

Zhenlun Gloss Black Monoblock Forged Wheels Gloss Black For Sports Car

-

Zhenlun Monoblock Forged Wheels Lightgrey With Machined Face

-

Zhenlun Monoblock Forged Wheels Gloss Black Dense Multi Spoke

0

0