Submit

Submit feedback

6061-T6 Aluminum Wheels: Understanding the Key Differences and Benefits

2025-01-03

6061-T6 Aluminum Wheel Manufacturer Factory Supplier

When it comes to high-performance automotive wheels, materials and construction play a crucial role in determining their strength, weight, and overall performance. Among the popular options in the automotive world are 6061-T6 aluminum wheels and monoblock forged wheels. Both types of wheels offer distinct advantages, but they also differ in terms of material, manufacturing processes, and application.

6061-T6 Aluminum Wheels: A Blend of Strength and Lightweight Design

6061-T6 aluminum is a high-strength alloy known for its exceptional durability, lightweight properties, and resistance to corrosion. It is often used in the aerospace industry but has also become a popular choice for making wheels in the automotive sector, particularly for performance-oriented vehicles. The “T6” in the 6061-T6 designation refers to the tempering process the alloy undergoes, which involves heat treatment and artificial aging to enhance its strength.

Advantages of 6061-T6 Aluminum Wheels:

Lightweight and Strong: 6061-T6 aluminum wheels offer a balanced combination of lightness and strength, which is essential for improving vehicle performance. Lighter wheels reduce unsprung weight, resulting in better handling, acceleration, and braking.

Corrosion Resistance: The alloy has an resistance to corrosion, making it ideal for vehicles exposed to harsh weather conditions, road salts, and moisture.

Affordability: Compared to other materials like forged alloys or carbon fiber, 6061-T6 aluminum is more cost-effective, making it a popular choice for both performance and regular driving applications.

However, while 6061-T6 aluminum wheels are highly durable, they are generally not as strong as forged wheels, and they may not be suitable for motorsports or vehicles exposed to very high stresses and impacts.

Monoblock Forged Wheels: Strength and Performance

Monoblock forged wheels are made from a single piece of high-quality metal, typically aluminum, through a forging process. The forging process involves applying pressure to the metal at high temperatures to shape it into the desired wheel design. This process aligns the metal’s grain structure, resulting in strength and performance. Unlike cast wheels, which are molded into shape, forged wheels undergo a more intensive manufacturing process that their strength-to-weight ratio.

Advantages of Monoblock Forged Wheels:

Increased Strength: Because of the forging process, monoblock forged wheels are much stronger than cast wheels or even wheels made from heat-treated alloys like 6061-T6 aluminum. This makes them highly resistant to bending, cracking, and deformation under heavy loads and conditions.

Lightweight Design: Despite their strength, monoblock forged wheels are relatively lightweight. The forging process allows for precision design, enabling the production of wheels with thinner, stronger sections, which helps to reduce overall weight without sacrificing strength.

Performance: Monoblock forged wheels are commonly used in motorsports due to their ability to withstand high forces and driving conditions. Their strength and lightweight properties contribute to improved acceleration, better handling, and faster lap times.

Aesthetic Appeal: The forging process also allows for more intricate and unique designs, which is why monoblock forged wheels are often chosen for their aesthetic qualities. Many custom wheel manufacturers offer a range of finishes, such as brushed, polished, or anodized, that enhance the appearance of the wheel.

Ultimately, the choice between these two types of wheels will depend on factors such as budget, vehicle application, and performance goals. For those who are looking for a robust, cost-effective option, 6061-T6 aluminum wheels offer an solution. However, for those who demand the level of performance and strength, monoblock forged wheels are the way to go, offering a combination of strength, reduced weight, and customizability.

recommend products

-

Zhenlun Multi Spokes Split Monoblock Forged Wheels Bronze With Silver Lip Edge

-

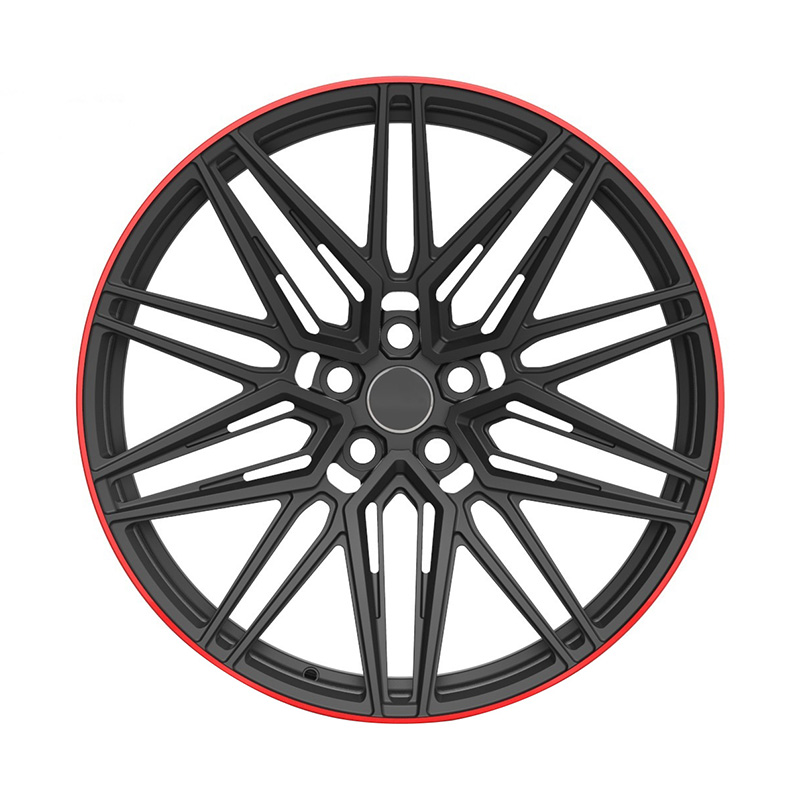

Zhenlun Matt Black With Red Lip Monoblock Forged Wheels

-

Zhenlun Gloss Black Monoblock Forged Wheels Gloss Black For Sports Car

-

Zhenlun Monoblock Forged Wheels Lightgrey With Machined Face

-

Zhenlun Monoblock Forged Wheels Gloss Black Dense Multi Spoke

0

0