Submit

Submit feedback

What Processes Do Forged Off-Road Truck Wheels Have to Go Through?

2024-11-08

Forged off-road truck wheels are some of the most durable and high-performance wheels available, designed to withstand the harsh conditions encountered in off-road driving. These wheels are created using a specialized forging process that ensures strength, weight reduction, and reliability under certain conditions. To understand how these wheels are made, it’s essential to break down the various processes involved.

1. Material Selection

The step in creating forged off-road truck wheels is selecting the right material. Typically, high-strength aluminum alloys are used because they offer a balance of strength, durability, and weight reduction. Materials like 6061-T6 or 7075 are commonly chosen due to their tensile strength and resistance to corrosion.

2. Forging Process

The forging process is what distinguishes these wheels from cast or stamped wheels. In this process, a solid billet of metal is heated to a specific temperature and then pressed under pressure. This compresses the metal’s grain structure, making it denser and stronger. The resulting wheel is more resistant to cracks, fatigue, and impact, making it ideal for off-road conditions where rocks, mud, and rough terrain can put significant stress on the wheels.

3. Machining and Shaping

Once the wheel has been forged, it is subjected to precision machining to shape it to the desired specifications. This includes trimming the wheel to remove any excess material and then drilling bolt holes for the wheel’s attachment to the vehicle. The machining process ensures that the wheel is balanced and meets strict performance and safety standards.

Basic Information of Fuel Forged Black Chrome Wheels

Fuel Forged Black Chrome wheels are a premium option for truck owners and automotive enthusiasts looking for both performance and style. These wheels are part of Fuel Off-Road's high-performance lineup, designed for trucks and SUVs that demand strength and durability for off-road adventures. The combination of black chrome finish and forged construction makes these wheels stand out in terms of both aesthetics and functional benefits.

Construction and Design

Fuel Forged Black Chrome wheels are crafted using a forging process, where a billet of high-quality aluminum is heated and shaped under pressure. This forging process ensures that the wheels have strength and are capable of withstanding the rugged conditions of off-road driving. The wheels are then machined with precision to meet strict tolerances, ensuring proper fitment and balance.

The design of Fuel Forged Black Chrome wheels emphasizes a sleek, aggressive look with a distinctive black chrome finish. The black chrome is a sophisticated treatment that provides a glossy, mirror-like appearance while maintaining durability. This finish not only adds an eye-catching aesthetic but also helps protect the wheel from the elements, ensuring that the wheels retain their appearance over time, even in harsh weather conditions.

Performance and Durability

As forged wheels, Fuel Forged Black Chrome wheels offer exceptional strength and resistance to damage. The forging process results in a denser and more durable material, which is critical when driving over rocky or uneven surfaces. These wheels are ideal for off-road enthusiasts who need wheels that can handle the stresses of terrain while maintaining performance and integrity.

In addition to their strength, these wheels are designed to be lightweight, which helps improve the overall performance of the vehicle. The reduction in unsprung weight enhances handling, acceleration, and braking, making Fuel Forged Black Chrome wheels a choice for both off-road and on-road driving.

recommend products

-

Zhenlun Multi Spokes Split Monoblock Forged Wheels Bronze With Silver Lip Edge

-

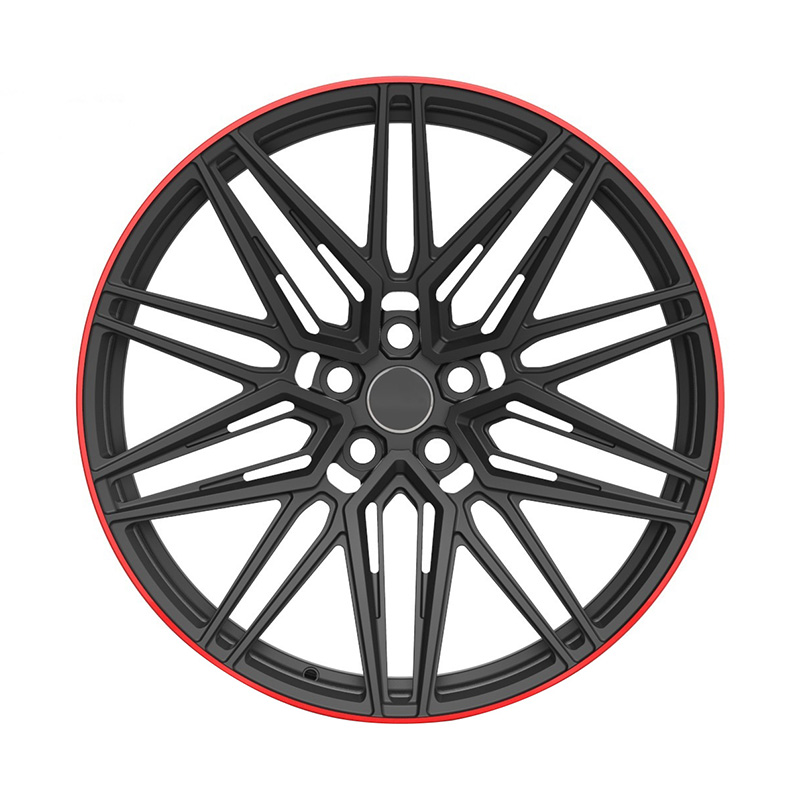

Zhenlun Matt Black With Red Lip Monoblock Forged Wheels

-

Zhenlun Gloss Black Monoblock Forged Wheels Gloss Black For Sports Car

-

Zhenlun Monoblock Forged Wheels Lightgrey With Machined Face

-

Zhenlun Monoblock Forged Wheels Gloss Black Dense Multi Spoke

0

0