Submit

Submit feedback

Quality Inspection of Forged Luxury Drag Racing Metal Wheels

2024-11-08

In the high-performance world of drag racing, the importance of selecting the right wheels cannot be overstated. Wheels are not just aesthetic elements—they are integral components that directly affect the vehicle’s performance, safety, and overall race results. One of the sought-after types of wheels in this space is the forged luxury drag racing metal wheel. Known for their strength, lightweight design, and exceptional durability, forged wheels are crafted with precision to meet the demands of high-speed racing. However, to ensure these wheels can perform under the conditions of drag racing, a stringent quality inspection process is essential.

For drag racers, performance and safety are paramount, and the wheels play a significant role in achieving both. A forged luxury drag racing metal wheel is made from high-quality aluminum that is subjected to an advanced forging process, which ensures its strength, toughness, and lightweight nature. However, no matter how advanced the manufacturing process, there is always the possibility of imperfections or material weaknesses that could compromise the wheel’s integrity. Therefore, comprehensive quality inspection is necessary to guarantee that each forged luxury drag racing metal wheel can withstand the intense stresses and forces encountered during high-speed drag races.

The manufacturing of forged luxury drag racing metal wheels is a highly specialized process, and it requires careful monitoring at each stage. Once the wheels are forged, they undergo a series of tests and inspections to ensure they meet the strict specifications required by competitive drag racing teams. This process is designed to eliminate defects and ensure that every forged luxury drag racing metal wheel will perform flawlessly when it counts.

The Key Phases of Quality Inspection

Visual Inspection

The stage of the inspection process involves a thorough visual examination of the forged luxury drag racing metal wheels. This step ensures that there are no obvious signs of defects, such as cracks, dents, or surface imperfections. Any irregularities in the finish, such as scratches or blemishes, are also identified at this stage. Since these wheels are designed not only for function but also for their high-end appearance, visual inspection plays a critical role in maintaining the luxury appeal of the product. Ensuring the wheels are free from cosmetic defects guarantees they are ready for both high performance and aesthetic appeal on the track.

Dimensional Checks

After the visual inspection, the forged luxury drag racing metal wheels undergo precise dimensional checks. This step ensures that each wheel conforms to the exact specifications outlined by the design engineers. Wheel size, offset, backspacing, and bolt patterns must be accurate to ensure proper fitment on the racing vehicle. Any deviation in these measurements, even by a small fraction, could be handling problems or, worse, a failure during a race. Precision in these dimensions is crucial, as it directly impacts how the wheel will interact with the tires and suspension system.

Tensile Strength Testing

One of the critical aspects of forged luxury drag racing metal wheels is their strength. Drag racing places demands on a wheel’s ability to handle rapid acceleration, high speeds, and heavy braking. The metal used in the wheels needs to withstand these forces without failure. Tensile strength testing is a vital part of the inspection process, as it determines the material’s resistance to breaking under tension. By applying controlled stress to the wheel material, manufacturers can ensure that the forged luxury drag racing metal wheels possess the strength necessary to endure the high-impact nature of drag racing.

Fatigue Testing

Fatigue testing is another essential aspect of the quality inspection process. This test simulates the repetitive stresses and strains a wheel will endure over time and under conditions. The forged luxury drag racing metal wheels are subjected to hundreds or even thousands of cycles of simulated forces that mimic what they would experience during actual races. This helps identify any weaknesses in the wheel's structure that could cause failure after prolonged use. A wheel that passes fatigue testing is guaranteed to perform consistently, race after race, without experiencing cracks or structural breakdown.

recommend products

-

Zhenlun Multi Spokes Split Monoblock Forged Wheels Bronze With Silver Lip Edge

-

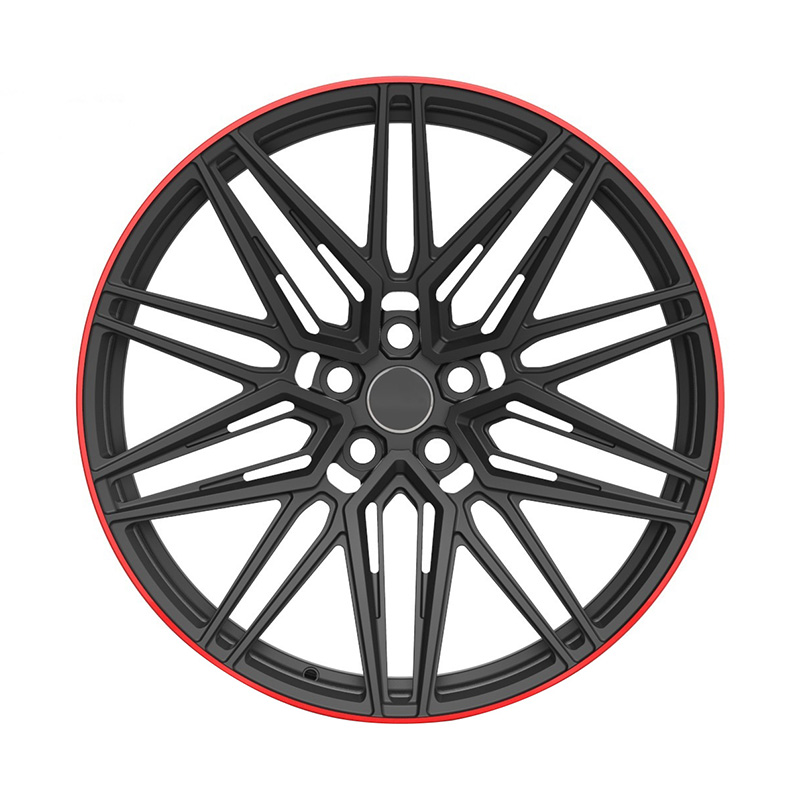

Zhenlun Matt Black With Red Lip Monoblock Forged Wheels

-

Zhenlun Gloss Black Monoblock Forged Wheels Gloss Black For Sports Car

-

Zhenlun Monoblock Forged Wheels Lightgrey With Machined Face

-

Zhenlun Monoblock Forged Wheels Gloss Black Dense Multi Spoke

0

0