Submit

Submit feedback

Forging Processes of Deep Dish Offroad Wheels

2024-11-08

Offroad wheels must endure conditions, from rugged terrains and high-impact obstacles to weather changes and corrosive environments. Deep dish offroad wheels, known for their aesthetic appeal and performance, owe much of their durability and functionality to advanced forging processes.

The Forging Process Explained

Forging is the process by which metal is shaped using heat and pressure, and it has been widely adopted in the manufacture of offroad wheels. Unlike casting, which pours molten metal into a mold, forging involves compressing the material to align its grain structure, bringing about stronger, more durable components. For offroad wheels, this method offers a critical advantage: enhanced strength-to-weight ratio. Forged wheels are considerably stronger and more lightweight than their cast counterparts, making them better suited to withstand the harsh conditions of offroad environments.

The process begins with a high-quality billet of aluminum, chosen for its strength and lightness. The billet is heated to a specific temperature to make it more malleable and less prone to cracking during shaping. The heated billet is then subjected to intense pressure, either through a press or hammer, to form the wheel shape. This process refines the grain structure of the metal, resulting in a much stronger and more cohesive material.

After forging, the wheel undergoes further machining to create the desired features, including bolt patterns, lip contours, and spokes. These wheels are then treated with heat to relieve any stress and enhance their strength further. The final result is a wheel with increased resistance to cracks, bends, and other forms of damage, making it ideal for offroad conditions.

Wheels are not just functional—they are a statement. The aesthetic design of 5x100 polished deep dish wheels exemplifies how form and function can coexist. These wheels are often chosen for their stylish appearance, but their design is far from superficial. The deep dish styling, which features a distinctive concave shape, is an iconic look in the automotive world, especially among enthusiasts who value both performance and appearance.

The deep dish wheel is characterized by a pronounced inward curve on its face, often creating a concave or dish-like appearance. This design element is not just visually striking; it also has practical benefits. The deep dish adds strength to the wheel, especially around the lip area, which is typically subjected to stress and impact during offroad adventures. In the case of 5x100 wheels, the deep dish style also helps distribute forces more evenly across the wheel’s surface, enhancing overall performance and durability.

From an aesthetic perspective, polished finishes further elevate the wheel’s look, giving it a gleaming, mirror-like shine that contrasts beautifully against the rugged nature of offroad vehicles. The polished finish accentuates the wheel’s curves, creating a dynamic interplay of light and shadow that emphasizes the wheel’s depth and complexity. For enthusiasts who appreciate the finer details, this polished effect highlights the craftsmanship of the wheel and makes it a visual focal point on the vehicle.

The 5x100 bolt pattern, a popular choice for many compact and sport-oriented vehicles, plays a significant role in the design of the wheel. It refers to the number of bolt holes (5) and the distance between them (100 mm). This configuration allows for both compatibility with a range of vehicles and an effective distribution of forces across the wheel. For the designer, this bolt pattern offers flexibility in the wheel’s aesthetic layout, balancing the need for strength and performance with the desire for style.

Designing 5x100 polished deep dish wheels involves careful attention to detail, particularly in how the spokes are arranged and how the dish is shaped. The spokes of these wheels are often designed to appear dynamic, often featuring an intricate or multi-spoke pattern that gives the wheel a sense of movement even when the vehicle is stationary. These spokes are not just about looks; they are strategically placed to provide strength while keeping the wheel as lightweight as possible.

Additionally, the contrast between the polished lip and the matte or brushed finish on the inner sections of the wheel creates a visually appealing texture. This combination of finishes highlights the depth of the dish and makes the wheel stand out on any vehicle, especially when combined with offroad tires that emphasize the wheel’s rugged performance.

recommend products

-

Zhenlun Multi Spokes Split Monoblock Forged Wheels Bronze With Silver Lip Edge

-

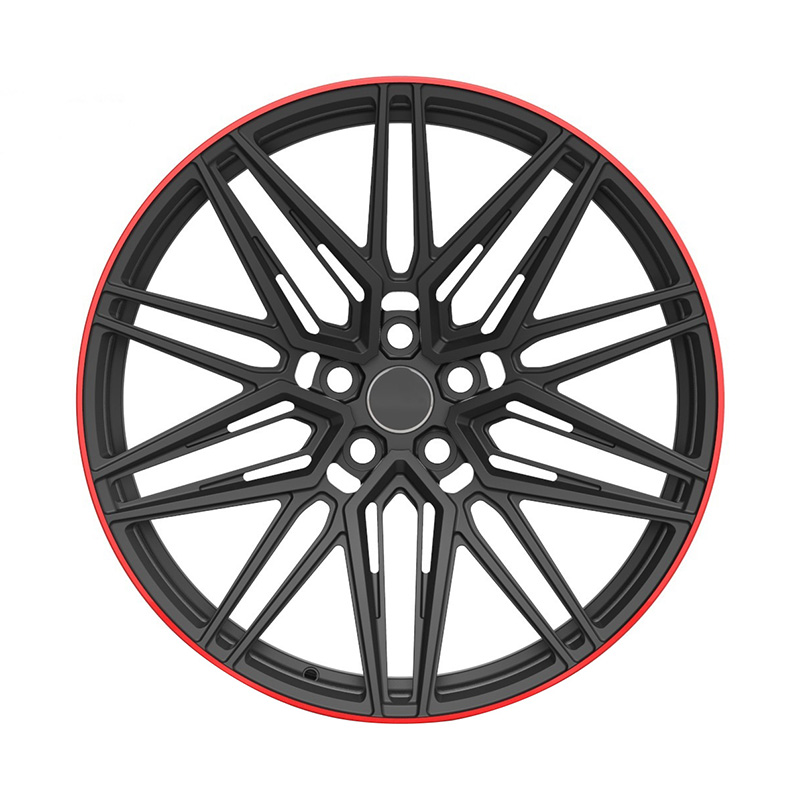

Zhenlun Matt Black With Red Lip Monoblock Forged Wheels

-

Zhenlun Gloss Black Monoblock Forged Wheels Gloss Black For Sports Car

-

Zhenlun Monoblock Forged Wheels Lightgrey With Machined Face

-

Zhenlun Monoblock Forged Wheels Gloss Black Dense Multi Spoke

0

0