Submit

Submit feedback

Understanding the Maintenance, Advantages, and Features of Deep Dish Wheels

2024-11-08

Deep dish bullet hole wheels are a popular choice for many car enthusiasts due to their distinctive style and rugged appearance. Their unique design often incorporates multiple cutouts or “bullet holes” around the wheel, adding to the wheel's aggressive look. However, like all wheels, deep-dish bullet hole wheels require proper care and maintenance to ensure they continue to perform well and maintain their aesthetic appeal.

The important aspect of maintaining deep dish bullet hole wheels is regular cleaning. Brake dust, dirt, road grime, and other debris can accumulate in the bullet holes and along the outer lip, which can cause corrosion or damage to the finish if left unchecked. To clean the wheels, it’s better to use a non-abrasive wheel cleaner and a soft-bristled brush. A brush with a narrow tip is useful for cleaning inside the bullet holes without scratching the surface. Avoid harsh chemicals or steel brushes, as these can damage the finish and cause pitting.

Inspecting for damage is also essential. Over time, deep dish wheels may encounter curbs or rough roads, which can cause dents, chips, or cracks. Check the wheels periodically for any visible signs of damage. If you find any, it’s important to address them promptly by taking the wheels to a professional for repair.

Another key factor in maintaining deep dish bullet hole wheels is keeping them properly balanced and aligned. Misalignment can cause uneven wear, affect handling, and damage the wheels or tires. Regular tire rotations and proper wheel alignment are crucial for the longevity of both the wheels and tires.

Deep dish honeycomb wheels are an exciting wheel design that combines a deep concave shape with a honeycomb-style pattern in the center. This style offers several advantages, making it a sought-after option for vehicle customization. These wheels are not only visually striking but also have a number of performance benefits.

The deep dish profile of these wheels is another advantage, as it provides a more aggressive stance to the vehicle, enhancing its appearance. The deeper lip gives the vehicle a bold, dynamic look that is good for custom cars or show cars. Additionally, the design of the honeycomb pattern can help reduce the stress placed on the wheel by distributing forces more evenly across the surface. This helps improve the overall durability of the wheel, making it resistant to bending or cracking under pressure.

Deep dish monoblock wheels are a sophisticated option for those looking for performance and aesthetics in one package. These wheels are made from a single piece of metal, typically forged aluminum, which makes them lightweight yet incredibly strong. The deep dish design, with its concave profile, gives the wheel a distinct appearance that stands out on high-performance vehicles and luxury cars.

One of the primary features of deep dish monoblock wheels is their strength-to-weight ratio. Because these wheels are made from a single block of material, they tend to be more structurally sound than multi-piece wheels. The process of forging the aluminum under high pressure creates a dense, uniform structure that resists cracking and bending, even under high stress. This makes monoblock wheels particularly suitable for high-performance applications, such as racing or track-day vehicles, where strength and lightweight construction are crucial.

Another key feature of deep dish monoblock wheels is their customizability. Despite being a single-piece construction, these wheels come in a variety of finishes, including matte, gloss, and polished options. You can also find these wheels in different sizes and depths, making it easy to choose a design that fits your specific aesthetic or performance needs. The deep dish shape enhances the visual appeal of the wheel, adding a sense of depth and making the vehicle appear more aggressive and dynamic.

recommend products

-

Zhenlun Multi Spokes Split Monoblock Forged Wheels Bronze With Silver Lip Edge

-

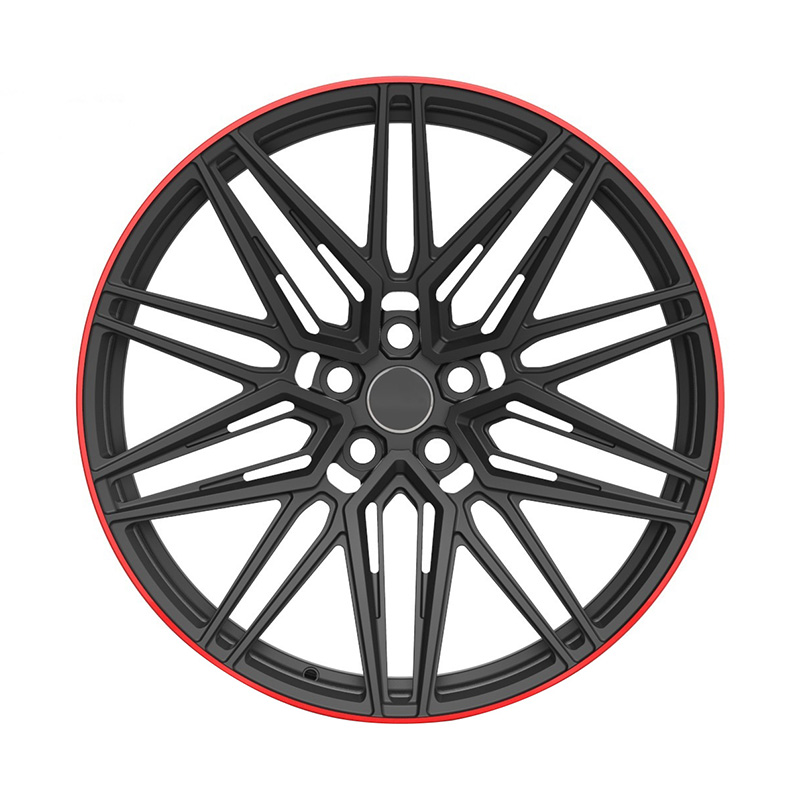

Zhenlun Matt Black With Red Lip Monoblock Forged Wheels

-

Zhenlun Gloss Black Monoblock Forged Wheels Gloss Black For Sports Car

-

Zhenlun Monoblock Forged Wheels Lightgrey With Machined Face

-

Zhenlun Monoblock Forged Wheels Gloss Black Dense Multi Spoke

0

0