Submit

Submit feedback

Forged Aluminum Off Road Alloy Wheels: Manufacturing Technology

2024-11-08

Upgrading to forged aluminum off road alloy wheels is a popular choice among truck and off-road enthusiasts. These wheels provide performance, strength, and aesthetic appeal, making them ideal for vehicles that face rugged terrains. The manufacturing technology behind these wheels and the design considerations involved in creating them are key factors that contribute to their success in demanding environments.

The manufacturing process of forged aluminum off road alloy wheels is an advanced technique that combines precision, strength, and lightweight properties, making these wheels cast or stamped alternatives. Forging involves the use of high pressure and heat to shape a solid billet of aluminum into a specific wheel shape. This process strengthens the metal by realigning the aluminum’s grain structure, making the final wheel more durable and less likely to crack or warp under pressure.

The step in manufacturing forged aluminum off road alloy wheels is selecting a high-quality billet of aluminum. The billet is heated to a specific temperature to make it malleable before it is placed into a mold or die. Hydraulic presses apply thousands of tons of pressure to mold the aluminum into the desired shape. This intense pressure eliminates air pockets and imperfections, ensuring the wheel is solid and consistent in strength.

Once the wheel shape has been formed, it undergoes several post-processing steps, such as CNC machining, polishing, and anodizing or powder coating, depending on the desired finish. The final product is a lightweight, durable wheel that is capable of withstanding the conditions often encountered during off-road driving, such as rocky terrain, deep mud, or uneven surfaces. Forged aluminum wheels are known for their strength-to-weight ratio, making them ideal for performance and off-road use.

When designing forged aluminum truck wheels, manufacturers must take into account several important considerations to ensure the wheels meet both aesthetic and functional requirements. Truck wheels are subjected to high stress, especially in off-road situations, so strength, durability, and safety are always top priorities. Here are some of the main design considerations for forged aluminum truck wheels:

Strength and Durability: The primary design concern for forged aluminum truck wheels is ensuring they can handle the weight and force placed on them, especially in off-road conditions. The wheel’s design must be capable of enduring the high impact from rough terrain, as well as the added stress from heavy loads or towing. The forging process naturally enhances the strength of the aluminum, but engineers may also design the wheel with reinforced spoke patterns or additional material in key areas to increase its load-bearing capacity.

Weight Reduction: A key benefit of forged aluminum wheels is their lightweight nature. Reducing the unsprung weight of the vehicle can better handling and improved fuel efficiency. Designers will often incorporate lightweight features into the wheel design, such as hollowed-out spokes or more minimalist designs, to help decrease the overall weight of the wheels without sacrificing strength. For trucks used in off-road conditions, lightweight wheels can improve performance by making the vehicle more responsive and easier to maneuver.

Wheel Offset and Backspacing: The offset and backspacing of a wheel are critical in ensuring proper fitment on the truck. These factors affect the alignment of the wheels relative to the truck’s suspension and body. Proper offset ensures that the wheels don’t rub against suspension components or the body of the truck, which could cause damage or affect handling. Manufacturers must carefully consider the specific truck model and its suspension system when designing forged aluminum truck wheels.

recommend products

-

Zhenlun Multi Spokes Split Monoblock Forged Wheels Bronze With Silver Lip Edge

-

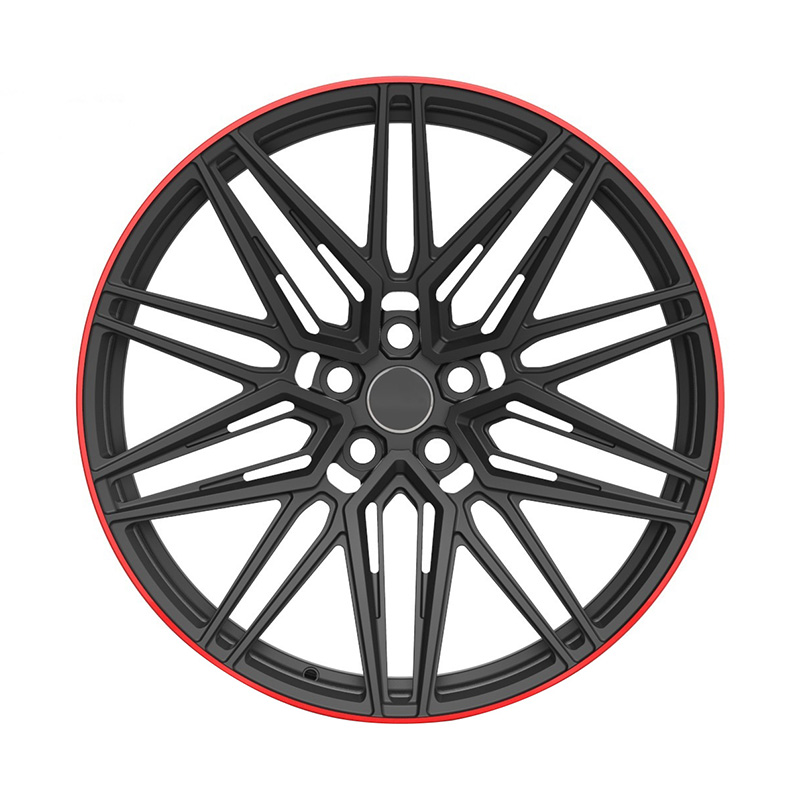

Zhenlun Matt Black With Red Lip Monoblock Forged Wheels

-

Zhenlun Gloss Black Monoblock Forged Wheels Gloss Black For Sports Car

-

Zhenlun Monoblock Forged Wheels Lightgrey With Machined Face

-

Zhenlun Monoblock Forged Wheels Gloss Black Dense Multi Spoke

0

0