Submit

Submit feedback

Enhancing Performance with Weld Beadlock Drag Racing Wheels

2024-11-08

Drag racing is an intense motorsport that demands precision, power, and performance from every component of a racing vehicle. Among the many factors that contribute to a vehicle’s success on the track, the wheels play an essential role in achieving grip, stability, and speed. One of the innovative advancements in wheel technology for drag racing has been the development of Weld Beadlock Drag Racing Wheels. These wheels have seen significant improvements over the years, contributing to enhanced performance for both amateur and professional drag racers.

The Evolution of Beadlock Technology in Drag Racing

Beadlock wheels have been a staple in off-road and drag racing vehicles for decades, but Weld Racing has taken beadlock technology to new heights with their advanced designs. Traditional wheels use a simple rim structure to hold the tire in place, but when drag racing tires are subjected to forces during launches, tire slippage and bead separation can occur, bring about inconsistent performance or even dangerous situations. Beadlock wheels, particularly those designed by Weld, tackle this issue by incorporating a beadlock ring and bolts that clamp the tire securely onto the rim, preventing the tire from slipping off the wheel during high-torque applications.

The primary advantage of beadlock wheels in drag racing is their ability to maintain consistent tire pressure under conditions. This innovation is particularly important in drag racing, where achieving traction during the launch is critical to securing a fast time. Weld Beadlock Drag Racing Wheels address the need for improved tire retention and pressure management, ensuring that tires remain firmly attached even during hard launches.

Improvements in Durability and Strength

One of the significant improvements in Weld Beadlock Drag Racing Wheels is their enhanced strength and durability. Early beadlock wheels were often heavy and prone to flexing under torque, bring about potential failure during high-performance racing. Modern Weld beadlock wheels, however, have been engineered with lightweight yet durable materials, such as forged aluminum and high-strength alloys, which provide greater resilience without adding unnecessary weight.

By reducing the weight of the wheels, Weld has improved overall vehicle performance by decreasing rotational mass. In drag racing, the ability to accelerate quickly is a major factor in performance, and any reduction in wheel weight can bring about faster acceleration times. At the same time, the durability of these wheels ensures they can handle the high stresses associated with drag racing, including high-impact landings, rapid acceleration, and deceleration. Weld Racing’s use of advanced materials, like aerospace-grade aluminum, allows these beadlock wheels to maintain their structural integrity over long racing seasons and extended use.

The beadlock ring itself is made from materials that resist corrosion and wear, ensuring that the wheels maintain their grip on the tires throughout multiple races. The addition of durable coatings, such as anodizing or powder coating, enhances resistance to the elements, ensuring the wheels stay in top condition even when exposed to the heat and stress typical of drag racing environments.

Improved Tire Management and Consistency

Weld Beadlock Drag Racing Wheels also excel in improving tire management, which is one of the key challenges in drag racing. Tire pressure management is critical for achieving the better possible launch and maintaining grip throughout the race. When tires are subjected to high forces during a drag launch, the bead of the tire can sometimes “break” or shift under heavy load, bringing about loss of grip and inconsistent performance. The beadlock design, by securely clamping the tire to the rim, eliminates the possibility of bead separation, allowing racers to run lower tire pressures without the risk of the tire coming off the rim.

Lower tire pressures are often used in drag racing to the tire’s contact patch with the track surface. By running at lower pressures, the tire can “flex” more effectively, providing more grip and traction on the track. However, this also increases the likelihood of bead separation, particularly in high-torque applications. Weld Beadlock Drag Racing Wheels solve this problem by locking the tire securely in place, ensuring the tire remains seated on the wheel, even under the conditions of a drag launch.

recommend products

-

Zhenlun Multi Spokes Split Monoblock Forged Wheels Bronze With Silver Lip Edge

-

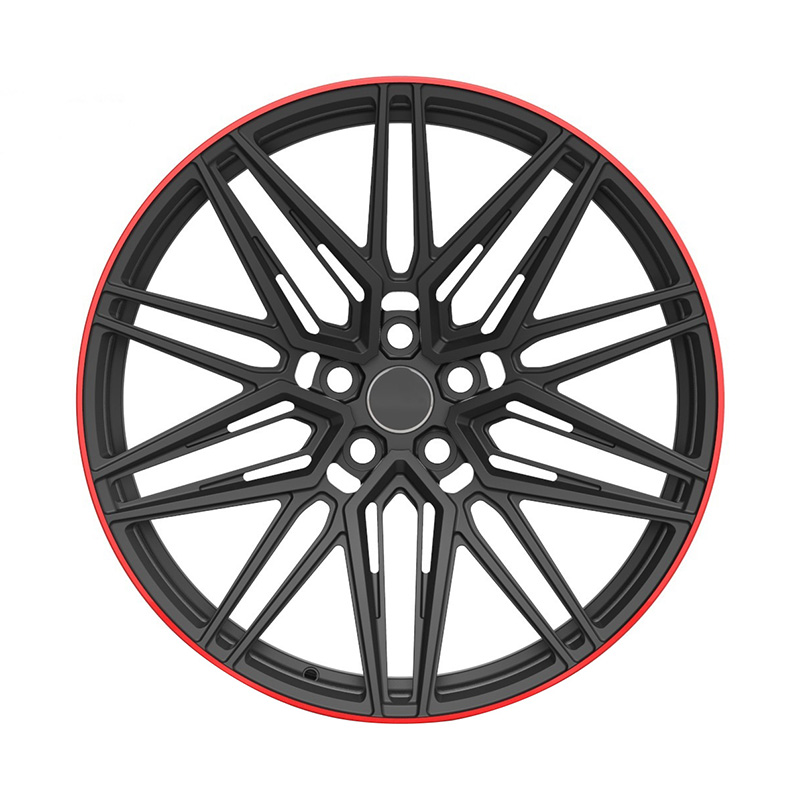

Zhenlun Matt Black With Red Lip Monoblock Forged Wheels

-

Zhenlun Gloss Black Monoblock Forged Wheels Gloss Black For Sports Car

-

Zhenlun Monoblock Forged Wheels Lightgrey With Machined Face

-

Zhenlun Monoblock Forged Wheels Gloss Black Dense Multi Spoke

0

0