Submit

Submit feedback

Unleash the Power of Offroad Performance with New Beadlock Forged Wheels

2024-07-01

Unmatched Durability and Strength

Beadlock Forged Wheels are crafted from high-quality materials using advanced forging techniques, ensuring they can withstand the harshest offroad conditions. The unique beadlock design provides a secure fit for the tire, preventing it from slipping or deflating under pressure, a common issue with standard wheels.

Enhanced Offroad Performance

With their robust construction, these wheels deliver traction and stability on various terrains, from rocky outcrops to muddy trails. The increased strength-to-weight ratio allows for better handling and control, making your offroad adventures smoother and more enjoyable.

Customization and Aesthetics

Offroad enthusiasts take pride in their vehicles, and the new Beadlock Forged Wheels offer a wide range of customization options to suit individual tastes. Available in various sizes, finishes, and styles, these wheels not only perform exceptionally well but also add a touch of sophistication to your offroad vehicle.

Easy Maintenance and Longevity

One of the standout features of these wheels is their low-maintenance nature. The durable construction means less frequent replacements and fewer repairs, saving you time and money in the long run. Additionally, the beadlock system simplifies the process of tire changes, making it a breeze even for those with limited mechanical experience.

Industry Endorsements

The offroad industry has taken notice of the benefits of Beadlock Forged Wheels, with many professional racers and offroad vehicle manufacturers endorsing their use. Their testimonials speak volumes about the reliability and performance these wheels provide in real-world offroad scenarios.

Wheels are a critical component of any off-road vehicle, especially when it comes to navigating tough, uneven terrain. Among the many innovations in wheel design, beadlock wheels have earned a special place for their ability to keep tires securely in place during off-road conditions. Chrome beadlock wheels, in particular, combine durability with aesthetic appeal, offering both performance and style.

Beadlock wheels were introduced to solve a common issue faced by off-road enthusiasts: tire bead separation. When driving on loose terrain or low tire pressure, the tire bead (the edge of the tire that seals against the rim) can sometimes slip off the rim, causing a dangerous loss of air pressure and control. Beadlock wheels were designed to address this problem by securing the tire bead to the wheel with a locking ring, which prevents the tire from separating even under conditions.

The concept of beadlock wheels emerged in motorsport, particularly in the realm of off-road racing and rock crawling, where tire performance is critical for safety and control. The need to keep tires securely in place during rigorous driving led to the development of various beadlock wheel designs, with improvements in strength, weight, and materials over time.

Chrome, as a finish for off-road wheels, entered the scene as manufacturers sought to combine the rugged durability of beadlock wheels with a sleek and reflective surface. Chrome plating offers both a high-gloss finish and corrosion resistance, making it a practical choice for wheels exposed to harsh weather conditions and rugged off-road environments. The glossy chrome finish not only improves the aesthetic appeal of off-road vehicles but also ensures that the wheels are resistant to rust and corrosion, maintaining their visual appeal for a longer period.

The origin of chrome beadlock wheels lies in the blending of two important demands: the practical need for tire retention during off-road driving and the desire for a durable, attractive finish. Today, chrome beadlock wheels are widely used in off-road vehicles, from rock crawlers to recreational trucks, combining function and style.

The 14-inch beadlock forged wheel is a popular choice for off-road vehicles due to its strength, lightweight construction, and ability to perform under challenging conditions. Forging, as a manufacturing process, involves shaping metal under high pressure, which results in a denser and stronger material compared to casting. Forged wheels are particularly favored in the off-road community because they offer strength, reduced weight, and increased durability.

recommend products

-

Zhenlun Multi Spokes Split Monoblock Forged Wheels Bronze With Silver Lip Edge

-

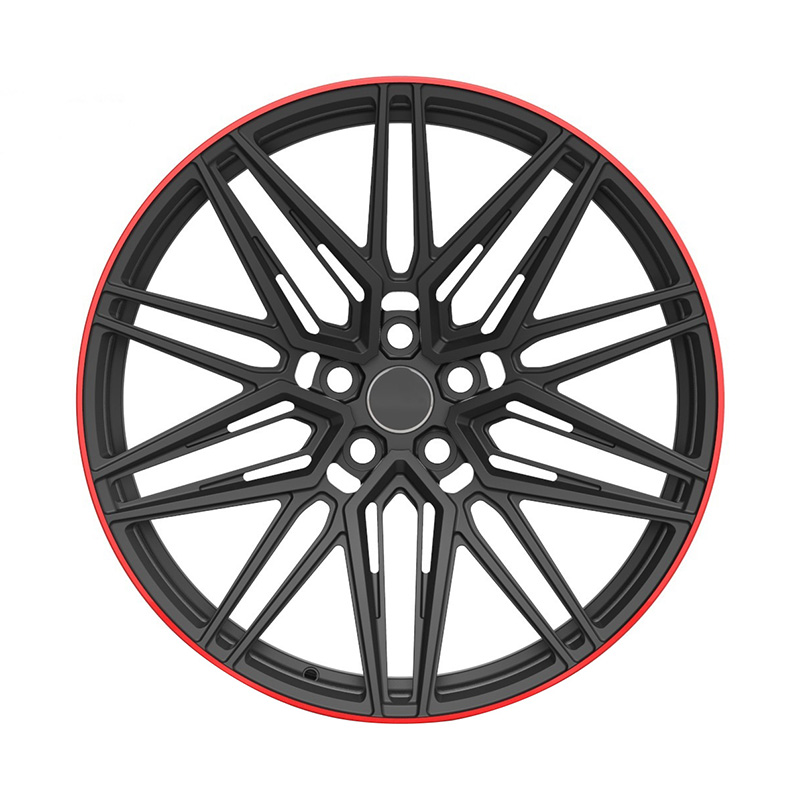

Zhenlun Matt Black With Red Lip Monoblock Forged Wheels

-

Zhenlun Gloss Black Monoblock Forged Wheels Gloss Black For Sports Car

-

Zhenlun Monoblock Forged Wheels Lightgrey With Machined Face

-

Zhenlun Monoblock Forged Wheels Gloss Black Dense Multi Spoke

0

0