Submit

Submit feedback

COMPANY PROFILE

ZHENLUN is an experienced and professional manufacturer that focuses on forged wheels and forged rims

due to highly skilled personnel, advanced equipment, and many years of cooperation experience with major buyers and brand owners ...01

12,000 TONS OF FORGED WHEELS

02

FOCUS ON HIGH QUALITY PRIVAT CUSTOMIZATION

03

PROFESSIONAL PRODUCTION AND PROCESSING

04

6061 AVIATION CLASS ALUMINUM ALLOY

-

Reasons to choose Zhenlun

Taizhou zhenlun takes style innovation as its responsibility, and the forged aluminum wheel has integrated and multi-piece (piece) combined design in structure.

ORIGINAL DESIGN MANUFACTURER

We have experienced team of designers and advanced equipment to support our customization service. Thus we are good at designing and producing products efficiently according to requirements of our clients.

-

EXPERIENCED PROCESSING WORKERS

Our workers in charge of each production process have many years of experience and professionalism to ensure that our products are more exquisite and beautiful.

PRODUCT TESTING

The products we produce can be reached by criteria for three tests, which include radial fatigue test, cornering fatigue test, and impact test.

-

HIGH-QUALITY FORGING BLANKS

We have a long-term cooperative relationship with the well-know suppliers of forging blank, and we only use high-quality blank to ensure the safety of our products. In addition, we can also purchase blanks required by suppliers.

-

01

Monoblock Forged Wheels

Monoblock Forged Wheels crafted from a single 6061-T6 aluminum forging. This ensures uniform density and structural integrity throughout the wheel, enhancing durability and performance under various driving conditions. Manufacturing ProcessMonoblock forged wheels are crafted from a single piece of high-grade aluminum alloy through a precision forging process. Unlike traditional wheels, which are cast or built from multiple components, monoblock forged wheels are shaped from a solid billet of aluminum. This process involves heating the aluminum to a malleable state and then applying extreme pressure to shape it into the desired form. The result is a wheel that is not only lightweight but also incredibly strong. The forging process enhances the structural integrity of the wheel by aligning the grain structure of the metal, which significantly increases its resistance to impact and deformation. This meticulous process ensures that every wheel is free from internal defects and inconsistencies that can affect performance. Strength and DurabilityThe monoblock forging technique results in wheels that are exceptionally strong, and capable of withstanding high loads and stresses encountered during aggressive driving or off-road adventures. This strength translates to enhanced safety and reliability for the driver. Optimized Lightweight DesignBy machining from a single forging, unnecessary weight is eliminated without compromising structural integrity. The lightweight nature of these wheels reduces unsprung mass, to improved handling, braking, and acceleration characteristics for the vehicle. Customization OptionsMonoblock Forged Wheels are available in a wide range of customizable finish options. From classic polished aluminum to modern matte black or custom colors, each wheel can be tailored to complement the aesthetic preferences of any vehicle owner. Cost ConsiderationsWhile monoblock forged wheels are typically more expensive than cast wheels, their cost is justified by their superior performance, durability, and customization options. The investment in high-quality wheels can lead to long-term benefits, including improved vehicle handling, reduced maintenance costs, and enhanced resale value. For enthusiasts and professionals who prioritize performance and aesthetics, the higher initial cost is often seen as a worthwhile investment. Our Monoblock Forged Wheels combine cutting-edge manufacturing techniques focusing on performance and customization. Ideal for enhancing both the performance and appearance of any vehicle, these wheels stand as a testament to precision engineering and innovation in automotive design.

-

02

2-Pieces Forged Wheels

Introducing our meticulously crafted 2-Pieces Forged Wheels, precision-engineered from premium 6061-T6 aluminum. These wheels epitomize strength, stiffness, and lightweight construction, making them ideal for automotive enthusiasts seeking performance. What Are 2-Pieces Forged Wheels?2-pieces forged wheels consist of two distinct parts: the wheel rim and the wheel center. The process begins with forging a high-quality aluminum billet, which is then machined into the wheel center. The rim, often made separately, is precisely shaped to fit the center. The two parts are then assembled using advanced techniques to ensure a perfect fit and optimal performance. Advanced Technology Forging Techniques: Modern forging techniques, such as rotary forging, enhance the properties of the wheel, resulting in a product that combines strength with reduced weight.Assembly Precision: The method of assembling the rim and center ensures that the wheel maintains its integrity and performance over time. Custom Colors & FinishesPersonalize your ride with our extensive range of custom colors and finishes for the 2-Pieces Forged Wheels. Whether you prefer a classic polished look or a bold matte finish, our selection allows you to match your vehicle's unique aesthetic. Each finish is applied with precision, showcasing the inherent elegance and quality of our wheels. Precision ManufacturingManufactured with meticulous attention to detail, our wheels exemplify precision engineering. Every aspect of the production process, from initial design to final assembly, adheres to strict quality standards. This commitment to excellence results in wheels that meet expectations, delivering reliability and performance under any conditions. Better Heat Dissipation The design of 2-pieces forged wheels often incorporates features that improve heat dissipation, which is essential for maintaining performance during high-stress conditions. Versatile ApplicationsPerformance Vehicles: These wheels are a popular choice for sports cars, racing vehicles, and luxury cars due to their high strength-to-weight ratio and customization options.Off-Road Capabilities: For off-road enthusiasts, 2-pieces forged wheels offer the durability needed to handle rough terrains and harsh environments. Experience the wheel technology with our 2-Pieces Forged Wheels, where precision meets performance to elevate your driving experience.

-

03

Offroad Beadlock Forged Wheels

Offroad Beadlock Forged Wheels are meticulously crafted from high-quality forged 6061-T6 aluminum, ensuring strength and durability. Engineered to excel in off-road environments, these wheels combine robust construction with exceptional performance. Strength and DurabilityCrafted from premium 6061-T6 aluminum through a precision forging process, Offroad Beadlock Forged Wheels offer nice strength and durability. This ensures reliability in challenging terrains and under conditions, making them ideal for off-road enthusiasts alike. Customizable Colors and FinishesAvailable in a range of custom colors and finishes, these wheels can be tailored to match any vehicle's aesthetic preferences. Whether you prefer a sleek matte black for a stealthy look or a vibrant metallic finish to stand out, our customization options allow you to personalize your off-road experience. Enhanced Off-Road CapabilityThe beadlock feature of our wheels provides enhanced off-road capability by securely clamping the tire to the wheel rim. This prevents tire deflation and ensures reliable performance even in challenging off-road conditions. Precision EngineeringEach wheel is meticulously crafted using advanced engineering techniques to ensure precise fitment and performance. Improved PerformanceBetter Traction: The beadlock system ensures that tires maintain maximum contact with the ground, improving traction and stability. This is particularly beneficial in challenging off-road conditions, such as loose gravel, mud, or sand.Reduced Slippage: With the tire bead securely locked in place, the likelihood of tire slippage is minimized. This allows for more controlled and predictable handling, enhancing the overall driving experience. Advanced Beadlock DesignSecure Tire Mounting: The beadlock ring clamps down on the tire bead, preventing it from coming off the rim during challenging off-road conditions. This feature is essential for maintaining tire integrity and performance.Enhanced Safety: By reducing the risk of tire blowouts and separation, beadlock wheels contribute to overall vehicle safety, allowing drivers to tackle difficult terrains with confidence. Trust in Our Offroad Beadlock Forged Wheels to deliver the durability, reliability, and style you deserve on every off-road journey.

recommend products

-

Zhenlun Multi Spokes Split Monoblock Forged Wheels Bronze With Silver Lip Edge

-

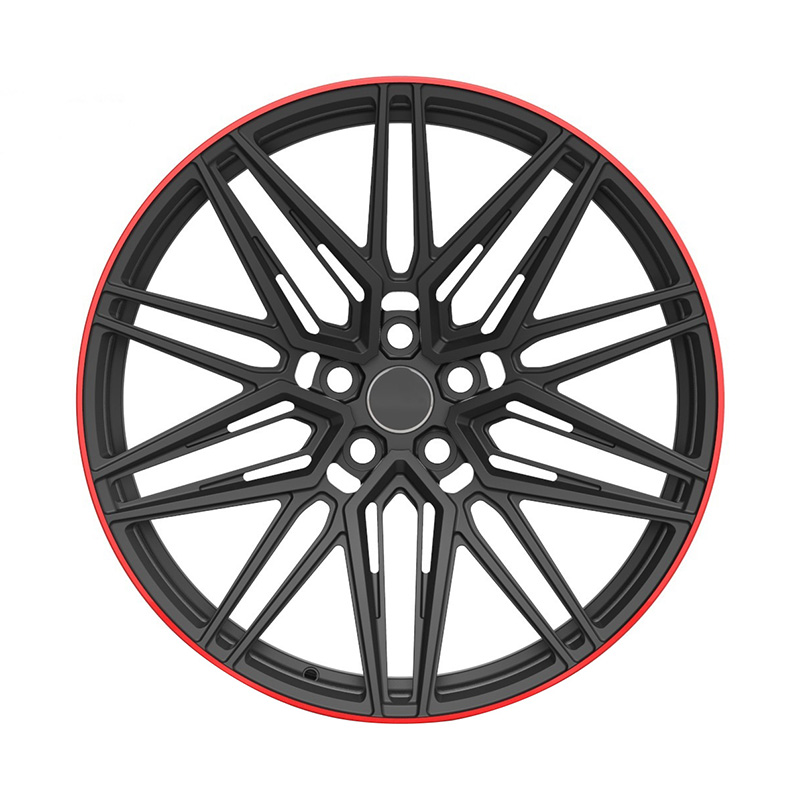

Zhenlun Matt Black With Red Lip Monoblock Forged Wheels

-

Zhenlun Gloss Black Monoblock Forged Wheels Gloss Black For Sports Car

-

Zhenlun Monoblock Forged Wheels Lightgrey With Machined Face

-

Zhenlun Monoblock Forged Wheels Gloss Black Dense Multi Spoke

-

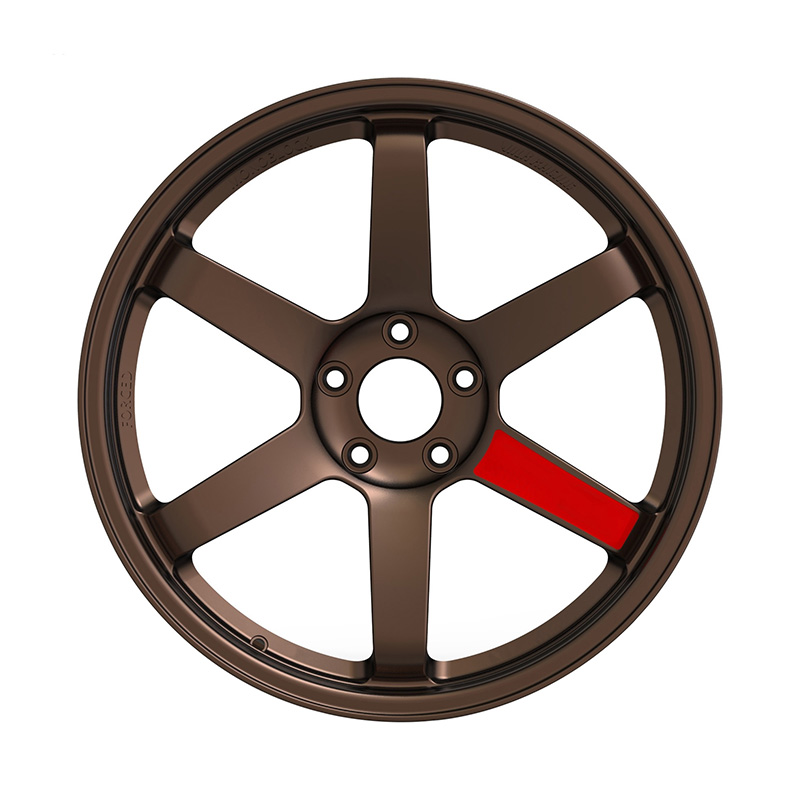

Zhenlun Bronze Deep Lip Concave Spoon Design Monoblock Forged Wheels

-

Zhenlun 5 Split Spokes Gloss Black With Machined Face Concave Forged Wheel For Car

-

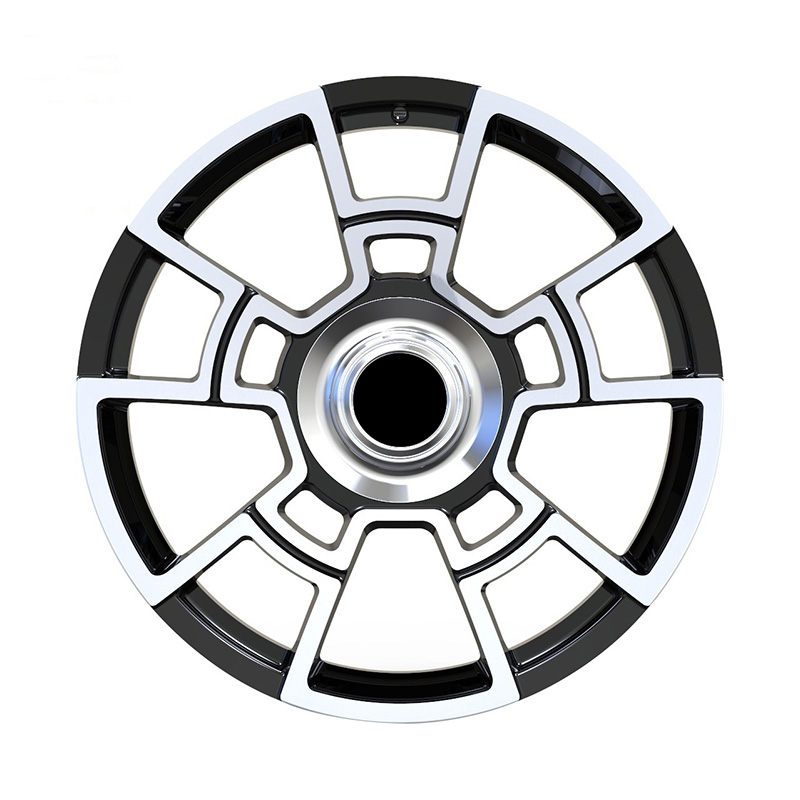

Zhenlun Gloss Black Suspension Cap Forged Wheel For Luxury Passenger Cars

-

Zhenlun Multi Spokes Luxury Car Sports Forged Rims With Floating Cap

-

Light Weight Multi Spoke Brushed Silver Sports Car Racing Forged Wheels

-

Zhenlun Light Weight Passenger Car Sports Forged Wheel Rim

-

Sports Car Racing Wheel Aluminum Alloy Forged Wheel Rim Hub

0

0